When New Hampshire’s legendary frugality meets with a cutting-edge business tool that private industries use to become more efficient, remarkable things begin to happen. Consider the results within state agencies and across our public higher education institutions in recent years.

At state agencies, more than 170 programs are now operated via “lean management”—a system of identifying waste, finding efficiencies and delivering services of higher quality and greater impact. For citizens, the results range from shorter waits at the Department of Motor Vehicles to fewer paperwork hassles at the Department of Health and Human Services.

At UNH, 21 programs are now operated using lean management, spurred on by the Project Management Office opened three years ago within UNH IT. Director Paul DeMello leads the group, which includes senior process engineer Dagmar Vlahos and senior technology manager Jean Spear, who have introduced lean management to more than 60 colleagues and worked with departments across campus. More than 20 UNH staff are also trained and state certified in lean management now. And from dining services to housing, UNH has reduced waste and streamlined operations.

That’s quite a boost, considering that University System of New Hampshire (USNH) institutions already operate about 30 percent more efficiently than peer institutions in the region.

“It’s a cultural and institutional change that is streamlining so many of the things we do here,” says DeMello, who is also chief of staff for UNH IT. “As a university, we’re always looking to seek out waste and find areas of improvement and efficiencies. But what lean management does is give us a process and uniform system that can help us be even more efficient.”

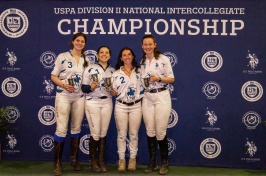

Last week, nearly 100 leaders of state agencies, USNH and the Community College System of New Hampshire gathered in Durham for the state’s third lean awards forum. It was the first time the forum has been hosted by UNH, and DeMello says it heralds the growing partnership between the state’s NH Lean Network and public higher education.

“The New Hampshire Lean Network offers a robust path for connecting us with comprehensive training tools to help us become more strategic and systematic in how we identify and eliminate waste,” says UNH president Mark Huddleston. “As we integrate these tools more fully across our campuses, they will allow us to better serve our state’s citizens, economy and visitors.”

Huddleston also noted that UNH is welcoming an expert in introducing lean management in New Hampshire, Chris Clement '94, who is joining UNH as vice president for finance and administration after serving as commissioner of the state Department of Transportation.

"Fortunately, there are a lot of excellent examples of lean process management at both the state level and at the university," says Clement, who starts at UNH on December 15. "Both of these institutions understand the importance of lean management to promote efficiency and quality and, ultimately, to provide even better service."

The creation of UNH’s Project Management Office was inspired by the university-wide strategic plan, launched in 2010: “UNH in 2020: Breaking Silos, Transforming Lives, Reimagining UNH,” which, among its top five requisites, called for “a budget system aligned with strategic priorities.” Its charge: “Where our current budget system fails to promote the goals of our strategic plan, we must recast the system itself.”

Gov. Maggie Hassan issued an executive order in 2013 creating the Governor’s Commission on State Government Innovation, Efficiency and Transparency, which brings together experts from the private business, nonprofit, higher education and local government sectors to make recommendations for modernizing state government, improving efficiency, measuring the performance of state agencies and improving transparency to citizens. Serving as its chair is Eric Herr, a member of the NH Charitable Foundation board of directors and former CEO of Autodesk.

“What we need is not a few projects that are innovative and efficient, but a state government that is lean and efficient,” says Herr, who was a keynote speaker at last week’s forum.

One of the simplest ways that citizens experience the impacts of lean management comes every time they drive through high-speed toll lanes on the state’s interstate highways. Instituting the automated toll lanes represents a lean process that cuts costs, saves fuel and reduces accidents and long lines at toll booths.

Tom Burack, commissioner of the state Department of Environmental Services, told forum attendees that lean management—also called “continuous process improvement”—requires organizations to embrace a culture of self-evaluation. That’s not always easy to do, he says, but it is critical to serving the public and building public trust. It is important that employees know that such efforts are not focused on reducing staff, he says, but on freeing up time and resources so that they can do more, do it better and, ultimately, gain more autonomy and satisfaction in their work.

“We’ve learned that it’s not only possible, but necessary,” Burack says, “and it improves our services dramatically.”

-

Written By:

Staff writer | Communications and Public Affairs