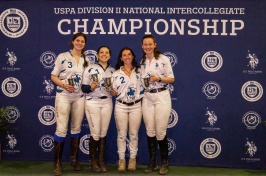

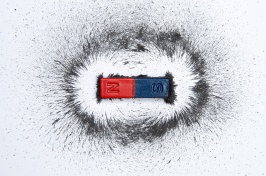

University Instrumentation Center director Shawn Banker showcases the UIC’s new 700 MHz nuclear magnetic resonance spectrometer, funded in part by a grant from the National Science Foundation. Below opposite: Sample images from the UIC’s scanning electron microscope.

Cutting-edge research requires cutting-edge technology. With significant innovations and investments in analytical instruments and scientists who operate them, UNH’s University Instrumentation Center (UIC) has become a leading resource for researchers at UNH and for academic and industry scientists throughout the region.

The University Instrumentation Center is more than a home for instruments — it is a healthy ecosystem of symbiotic relationships that span researchers, students and industry professionals.

Established in 1973, the UIC is a university-wide core facility — a central shared resource — with state-of-the art instruments and expertise. The recent addition of two shared labs on the UNH campus and expanded user services have positioned the UIC as one of the leading instrumentation facilities in the New England region.

“When I came here, I saw a lot of underutilized talent and instrumentation,” says Shawn Banker, UIC director since 2014. “We have upgraded our services by providing external users access to instrumentation within the UIC and across campus, added a remote monitoring service and expanded our instrument calibration and repair services.”

The center’s newest acquisitions exemplify its commitment to enhancing the university’s research capabilities. A Zeiss Versa 610 X-ray microscope, funded by a National Science Foundation (NSF) grant to New Hampshire BioMade, allows for high-resolution 3D models that let researchers characterize the properties and behaviors of materials.

The Bruker Biospin 700 MHz nuclear magnetic resonance spectrometer, which uses technology similar to magnetic resonance imaging, is widely used in biotechnology chemistry and medicine to understand the structure and motion of molecules as well as to analyze complex chemical and biological systems. The instrument was funded by a $1.6 million NSF grant to Krisztina Varga, assistant professor in the department of molecular, cellular and biomedical sciences (MCBS), with the university contributing an additional $700,000 in matching funds; Varga will share the instrument with other researchers at UNH, at other academic institutions and in industry.

To that end, the UIC is more than a home for instruments — it is a healthy ecosystem of symbiotic relationships that span researchers, students and industry professionals.

“One of the things that is really critical to having high-end instrumentation is that there is a mechanism in place to maintain the instruments as well as to train users to operate the instruments,” says Rick Cote, MCBS department chair. “The UIC excels on both of these fronts, and they play a central role in providing the basic training for students, faculty and staff to use these instruments themselves.”

Banker estimates that some 30 industry users — typically manufacturers — use UIC services each year, often opening the door to deeper relationships with UNH research. Of particular interest to industry professionals are UIC’s expert analysis services, including remote capability, which allows customers to watch and participate in a sample run in real time, without any need to travel.

“Working with Shawn was outstanding — he was accommodating and let us get trained and certified so that now we can operate the scopes ourselves,” says Jay Hoying, partner and chief scientist at Advanced Solutions Life Sciences (ASLS), a regenerative medicine company that relocated to New Hampshire to work with the Advanced Regenerative Manufacturing Institute. Hoying also uses the remote services, particularly for UIC’s scanning electron microscope, or SEM. “In real time, we can see the images as they’re coming off the SEM and direct what’s being done. It’s a fantastic solution.”

Hoying’s work with the UIC has also led to learning and job opportunities for UNH students. Russell Carr, professor of chemical engineering, has brought students from his tissue fabrication course to the ASLS facility to explore bioprinting from an industry perspective. Hoying and Carr’s work together even resulted in a UNH summer intern at ASLS.

“Core facilities like the UIC are a gateway in and out to different community members,” Hoying says. “Thanks to their company-friendly approach, we get to be another asset in this community of scientists.”

-

Written By:

Lily Greenberg '21G | Grad School