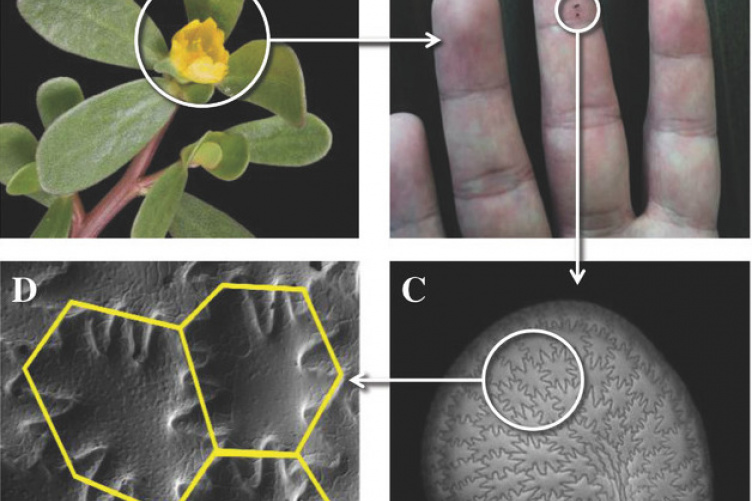

The purslane seed (clockwise from top left): In the flower, the seed, scanning electron microscope image of the seedcoat, magnified area of the seedcoat. (Photo: UNH)

Inspired by elements found in nature, UNH researchers say the puzzle-like structure of the delicate seed coat of plants like purslane could hold the secret to creating new smart materials strong enough to be used in items like body armor, screens and airplane panels.

“By learning from nature it may be possible to tailor the geometry and create the architecture for a smart material that can be programmed to amplify strength and toughness but also be flexible and have many different applications.”

“The seed coat’s major function is to protect the seed, but it also needs to become soft to allow the seed to germinate, so the mechanical property changes,” says Yaning Li, associate professor of mechanical engineering. “By learning from nature it may be possible to tailor the geometry and create the architecture for a smart material that can be programmed to amplify the strength and toughness but also be flexible and have many different applications.”

The research, published in the journal Advanced Materials, shows that the waviness of the mosaic-like tiled structures of the seed coat, called sutural tessellations, plays a key role in determining the mechanical response. Generally, the wavier it is, the more an applied load can effectively transit from the soft wavy interface to the hard phase, and therefore both overall strength and toughness can simultaneously be increased.

The building blocks of the seed coat are star-shaped epidermal cells which move by zigzag intercellular joints to form a compact, tiled exterior that protects the seed inside from mechanical damage and other environmental stresses such as drought, freezing and bacterial infection. To better understand the relationship between the structural attributes and functions of the seed coat’s unique microstructure, Li and her co-authors — including her doctoral student Chao Gao and postdoctoral researcher Benjamin Hasseldine — designed and fabricated prototypes using multi-material 3D printing. They then executed mechanical experiments and finite element simulations on the models.

“Imagine a window, or the exterior of an airplane, that is really strong but not brittle,” said Li. “That same concept could create smart material that could be adapted to behave differently in different situations whether it’s a more flexible body armor that is still protective or another such materials.”

Inspired by Nature

Mechanical engineering professor Yaning Li looks to nature’s shapes and structures to create innovative new materials.

The researchers say that the design principles described show a promising approach for increasing the mechanical performance of tiled composites of man-made materials. Since the overall mechanical properties of the prototypes could be tuned over a very large range by simply varying the waviness of the mosaic-like structures, they believe it can provide a roadmap for the development of new functionally graded composites that could be used in protection, as well as energy absorption and dissipation. There is a pending patent which has been filed by UNHInnovation, which advocates for, manages and promotes UNH’s intellectual property.

In addition to Li, Gao and Hasseldine, researchers from Virginia Tech and the Wyss Institute at Harvard University contributed to this paper. This work was supported by National Science Foundation and U.S. Air Force Office of Scientific Research.

For more information on licensing this patent-pending technology, contact unh.innovation@unh.edu.

-

Written By:

Robbin Ray ’82 | UNH Marketing | robbin.ray@unh.edu | 603-862-4864