Elizabeth Mamros '18 '23G, a doctoral student in mechanical engineering, was recently awarded a pair of fellowships to conduct research at the Institut für Umformtechnik und Leichtbau (IUL) in Dortmund, Germany.

The third-year student and Pennsylvania native received a Fulbright fellowship and a National Science Foundation Institute of International Education Graduate International Research Experiences (GIRE) fellowship. She plans to conduct research with novel manufacturing processes, particularly focusing on incremental forming technologies.

As an undergraduate, Mamros says a study international experience in Spain was transformative and planted the seed to seek out fellowships for similar opportunities at the graduate level as she works toward her goal of becoming a faculty member in higher education.

“This international collaboration experience will create connections that will spark additional collaborations in the future,” says Mamros, who will be on site for 13 months beginning in mid-June. “Germany was selected due to the IUL being the only laboratory that has the equipment and expertise required to host my research.”

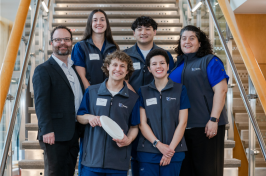

As a student at UNH, Mamros has been active at the John Olson Advanced Manufacturing Center and with NH BioMade, a five-year EPSCoR Research Infrastructure Improvement project funded by the National Science Foundation. She’s also served as a mentor in the STEMbassadors program, which provides inspiration, role models and hands-on STEM experiences to elementary and middle school students in New Hampshire.

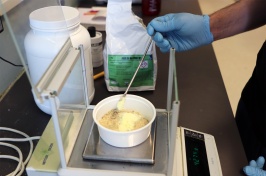

Mamros’ research focus at UNH is sheet metal forming technologies, such as incremental forming, and creating heterogeneous, biocompatible hardware for trauma fixation. She’s recently worked on characterizing different grades of stainless steel and will soon be moving to titanium. From her experience in Germany, she seeks to gain a fundamental understanding of how to vary the deformation paths during forming to manipulate the final part properties based on the intended application. For the NH BioMade project, this application is trauma fixation hardware, such as a cranial implant.

“In addition to the future international collaborations and expanding my network, I expect this project to promote cultural exchange and mutual understanding by sharing experiences from American and German manufacturing researchers and educators and by combining research efforts to solve global, industrial issues,” says Mamros.

-

Written By:

Brooks Payette | College of Engineering and Physical Sciences