It’s not just for the farmers market any more: “Fresh, local, sustainable” describes how UNH powers its 5 million square-foot campus. Now, the university’s newest source of electricity — hydropower from three small New Hampshire dams — could even be described as “artisanal.” UNH is among just a few universities in the nation using so-called micro hydropower.

“UNH has definitely been one of the leaders in higher education for seeking out unique ways to use renewable energy, especially local renewable energy, to meet our climate action needs,” says Matt O’Keefe ‘97, UNH’s director of energy and utilities.

Since 2009, the university’s ultra-efficient cogeneration power plant has been fueled primarily by the innovative EcoLineTM landfill gas-to-energy project that pipes purified methane gas from a nearby landfill to “cogen” — the combined heat and power plant. That plant generates electricity then captures the waste heat normally lost during that process to heat and cool campus buildings.

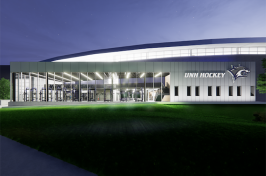

Steels Pond Hydro in Antrim, New Hampshire, is one of three small hydropower facilities UNH has partnered with to fulfill electricity needs on the Durham campus.

Video

While cogen provides nearly all campus energy needs, UNH has always purchased about 10 percent of its power from the electric grid. Within the past year, spurred by an energy accounting policy called group net metering, UNH has partnered with three small hydropower facilities — Steels Pond Hydro in Antrim, Ampersand Energy Partners in Groveton and Fiske Hydro in Hinsdale — to provide that last 10 percent, about eight million kilowatt hours (kWh), of purchased power.

Buying power from these small utilities will shave an estimated $200,000 per year from the university’s $1 million imported electricity bill. And, as Steels Pond founding partner Lori Barg notes, hydropower from existing dams is as clean as the bucolic streams and ponds that provide it.

“The beauty of water is you can use it over and over,” she says. Indeed, her facility, where a concrete dam has created Steels Pond from the north branch of the Contoocook River, began fueling production of the Goodell Company’s knives and once-famous apple parers in 1909.

According to Barg, just 80 of New Hampshire’s estimated 6,000 dams are producing power. In a further parallel to the local food movement, local hydropower keeps additional economic benefits — from power plant salaries to the local taxes the hydropower plants pay — close to home.

Back on campus, O’Keefe notes that UNH has another important arrow in its energy quiver: efficiency. With seed money from the American Recovery and Reinvestment Act (ARRA) in 2009, UNH launched a revolving fund that supports new energy efficiency projects on campus then plows the savings from those projects back into the fund. O’Keefe estimates the campus has seen more than $2 million in savings from projects like efficient lighting retrofits across campus and a passive solar heating system in Kingsbury Hall.

While Yankee thrift is a driver of UNH’s energy efficiency and power choices, they’re more than feel-good decisions. In 2007, UNH was among the first universities nationwide to sign the American College & University President’s Climate Commitment, a binding agreement to achieve carbon neutrality.

“UNH has a climate action plan that sets goals for us to try to achieve carbon neutrality by 2100,” says O’Keefe, noting that one of the first milestones commits UNH to reducing its greenhouse gas emissions by 50 percent by 2020 (2001 is the baseline). “To do that, we need to drastically change how we use energy sources here on campus.”

Learn about UNH's dual major in sustainability here.

-

Written By:

Beth Potier | UNH Marketing | beth.potier@unh.edu | 2-1566