It’s no fish tale: Farming fish can help grow plants. Researchers at the New Hampshire Agricultural Experiment Station at UNH are looking at integrated farming systems as a way to improve energy and resource utilization and monetize otherwise costly treatment processes.

A new aquaponic greenhouse at the UNH-based New Hampshire Agricultural Experiment Station aims to provide a model for integrating land-based aquaculture systems with hydroponic plant production that can be used locally and regionally to increase sustainable food production.

“Over half of the world’s seafood is produced from aquaculture,” said Todd Guerdat, assistant professor of agricultural engineering, who is leading the project at UNH’s Kingman Research Farm, an experiment station facility in Madbury. “Eighty percent of the seafood we eat in the United States is imported, resulting in nearly an annual $11 billion trade deficit for seafood alone. We need to take control of our food production systems by developing a sustainable, U.S.-based aquaculture industry.”

“Supporting sustainable agriculture in the Northeast United States requires a renewed focus on integrating agricultural production systems, such as combining recirculating aquaculture systems and hydroponic crop production. Agricultural systems become more economically viable when integrated and provide an ideal farming model that produces fish and plants for food, both locally and sustainably,” Guerdat said.

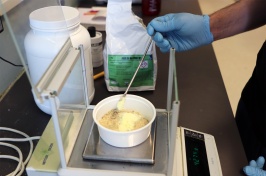

The new aquaponic research facility at Kingman Farm will allow scientists to evaluate hydroponic plants grown using water from a recirculating aquaculture system fertilized with nutrients from the food fed to fish. Using three identical greenhouses, researchers will develop an economically sustainable aquaponic production system design.

Specifically, scientists are investigating how to balance nutrient production from the fish and nutrient uptake by the plants, studying food safety concerns, developing integrated pest management (IPM) solutions, and optimizing the designs based on economic modeling. They plan to demonstrate the results to producers by offering hands-on workshops covering a full range of topics, including hydroponics, aquaculture, and integrated aquaponic system design and operation.

The new aquaponic research facility at Kingman Farm will allow scientists to evaluate hydroponic plants grown using water from a recirculating aquaculture system fertilized with nutrients from the food fed to fish.

“In an age where growing, buying, and eating locally improves food security for all, food production systems that are sustainable economically and environmentally are more important than ever. Recirculating aquaculture businesses are already in use in New Hampshire and the Northeast. However, there are many questions that remain. How do you balance the fish and plant production systems? How big should each be? What are realistic production estimates for business plan development? What is the most efficient design for a recirculating aquaculture system? This research aims to answer all of these questions so anyone – a farmer or individual grower – can take the results and apply them directly to their own application,” Guerdat said.

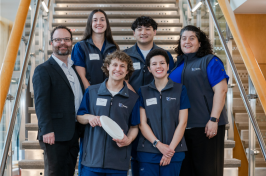

The research project has received extensive support and interest from local restaurants and chefs, as well as those in the food retail industry. Earlier this summer, 35 executives from Ahold Delhaize, one of the world’s largest food retailer groups that includes Hannaford, Stop and Shop, and Peapod, visited the new facility while it was under construction.

“This research is key to our industry. For instance, an aquaponics facility that can produce strawberries late into the season would mean that we can ensure high quality food throughout the year. On their own, our suppliers, who are often local suppliers, do not have the capabilities to run this type of research,” said Megan Hellstedt, vice president of sustainable retailing from Ahold Delhaize.

“The fish taste fantastic,” said Lee Frank, chef at Otis in Exeter who recently served fish raised in the new UNH system to restaurant patrons.

The initial test runs for the facility are already bearing “fruit” (vegetables, fruit, and fish). Researchers met a huge milestone met in August when they hit their production goal on their first run of Boston butter head lettuce. They grew the lettuce in 35 days from seed to harvest and hit the magical 150g head weight using only nutrients from the fish.

This material is based upon work supported by the NH Agricultural Experiment Station, through joint funding of the National Institute of Food and Agriculture, U.S. Department of Agriculture, under award number 1010110, and the state of New Hampshire. This research also is supported by NH Sea Grant and the USDA Agriculture and Food Research Initiative. Learn more about some of the research being conducted at this facility.

-

Written By:

Lori Tyler Gula, PhD | NH Agricultural Experiment Station | lori.gula@unh.edu | 603-862-1452