Marko Knezevic, assistant professor of mechanical engineering, received a prestigious CAREER award from the National Science Foundation.

Improved fuel efficiency of automobiles and aircraft depends, in part, on lighter, stronger materials. But how do you create those materials, and how do you know when they’ll fail? To help him answer those questions, the National Science Foundation has awarded Marko Knezevic a CAREER award.

Knezevic, an assistant professor of mechanical engineering at UNH, is particularly interested in materials such as titanium and magnesium alloys, both strong, lightweight metals with a hexagonal structure. “They have the potential for reducing weight in both aerospace and automotive industries,” he says. “But industry hasn’t been adopting much of them mainly because their fracture behavior is not well understood.”

“You could revolutionize the automotive industry or the aerospace industry or any industry working with lightweight metals with this research.”

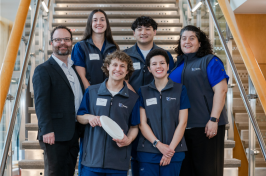

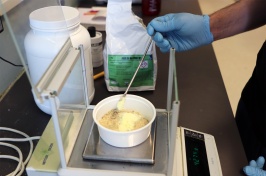

Working with a team of 10 graduate and undergraduate students, Knezevic will take a three-step approach to understanding the strengths and literal weaknesses of these metals: material testing in the lab, applying various types of loads to see how they fracture, characterization of the materials under the microscope. Finally, the researchers will apply what they’ve learned to model how the material will behave under different circumstances.

Such predictive modeling, says Knezevic, results in significant savings of time and money because it is done on a computer rather than on a shop floor.

The self-deprecating Knezevic notes that while his research may not seem as exciting as other projects —“If somebody offers you the chance to do this work or listen to whales singing, you’re going to listen to the whales” — its potential impact is large. “Any incremental advance in materials science is a significant jump,” he says. “You could revolutionize the automotive industry or the aerospace industry or any industry working with lightweight metals with this research.”

-

Written By:

Beth Potier | UNH Marketing | beth.potier@unh.edu | 2-1566