It sounds impossibly futuristic, but it’s actually the future: a new New Hampshire-based industry built around efforts to manufacture regenerative human tissue, and possibly even organs, for transplantation.

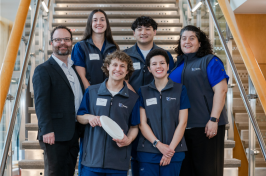

In December, UNH was tapped as one of three Granite State institutions that will lead a major national public-private initiative to develop biologically engineered cells and tissues that might potentially be used to manufacture new skin for combat-scarred U.S. soldiers or to preserve the organs of Americans waiting for transplants. Funded by a five-year, $80 million grant from the U.S. Department of Defense combined with more than $214 million from 80 industry, education and nonprofit partners, the so-called Advanced Regenerative Manufacturing Institute (ARMI) will be led by Manchester-based DEKA Research & Development, in partnership with UNH and Dartmouth-Hitchcock. UNH will spearhead the national education and workforce development activities for ARMI, drawing on its growing life sciences strength as well as its leadership in creating powerful partnerships to drive economic development in the state.

“We are honored by this recognition from the Department of Defense for our leadership in STEM education and workforce development,” UNH President Mark Huddleston says.

ARMI is the 13th undertaking of Manufacturing USA, an initiative launched by the Obama administration in 2011 to encourage innovation in manufacturing by “moving promising, early-stage research into proven capabilities ready for adoption by U.S. manufacturers.” The institute will be headquartered in Manchester’s historic millyard, where DEKA founder Dean Kamen hopes it might do for the Manchester millyard what the industrial revolution did for the city when Manchester was the largest industrial center in America.

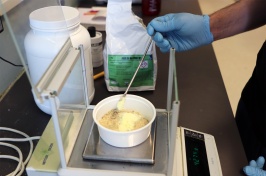

The institute will initially focus on solving some of the obstacles that currently stand in the way of viable tissue and organ bioengineering, such as improving the availability, reproducibility, accessibility and standardization of manufacturing materials, technologies and processes. That means engineered organs and limbs aren’t right around the corner, but they’re not necessarily the stuff of science fiction, either.

Originally published in UNH Magazine Spring 2017 Issue

-

Written By:

Kristin Waterfield Duisberg | Communications and Public Affairs