Editor's Note: This is the latest installment in our ongoing series featuring UNH faculty sharing their stories in their own words.

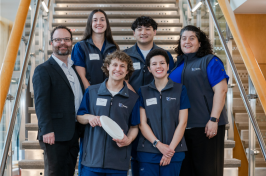

Russell Miles, senior lecturer, decision sciences, Paul College of Business and Economics

“Growing up in East Rochester, New Hampshire, my friends and I would often go exploring in an old abandoned shoe factory near my house. Well, technically, it was trespassing, but it was fun, and I was fascinated by the dusty old machines. Around that time, my dad was a quality engineer at Sanders Associates (now BAE Systems) in Nashua. One of my earliest memories is visiting his engineering lab and touring the factory floor. When I was around 8, we were on vacation in North Carolina and my dad took us on a tour of a cigarette factory. The automated production line was loud and exciting. Basically, I’ve wanted to work in factory operations since I was a kid.

I’ve always been interested in seeing how things work and I was really good at taking things apart. My mom will tell you that I was not always that good at putting things — like her vacuum cleaner — back together. In high school I worked part-time at two local factories; one made power supplies and the other, machine tools. In my spare time I worked on my own projects, like souping up my brother’s go-cart or customizing junky old electric guitars. Once I even rewired an old boombox into a cheap home studio so I could make multitrack recordings.

My interest in making machines led me to a mechanical engineering major at UNH. When I was a junior I started taking classes toward my MBA and earned a bachelor’s degree in mechanical engineering and an MBA in five years. During that fifth year, GE recruited me into their manufacturing management program (MMP).

After graduation I joined GE Aircraft Engines in Lynn, Massachusetts, and worked as a shop supervisor on the second shift. I was finally working full-time in a factory, making cool jet engines, but I felt like I was in over my head. It was a challenge trying to supervise a group of hardcore union machinists, but I learned a lot from those guys during that first year on the job.

My next MMP rotation was as a manufacturing engineer at GE Aerospace in Binghamton, New York, writing wiring instructions for sonar equipment. After that, I moved on to GE Astrospace in East Windsor, New Jersey, where I managed a team that was assembling and testing modules that went in to satellite systems.

At that point, I thought I would stay with GE for the rest of my career. But then they sold their Astrospace division to Lockheed Martin Aerospace. By networking with my former GE colleagues, I was able to shift gears into operations consulting and ended up working with clients such as Citigroup, Allied Signal, Gateway Computers and Exelon. As the U.S. manufacturing landscape changed, my consulting focus shifted from factory operations to strategic sourcing and supply chain management.

After our second child was born my wife, Linette, and I decided to move back to New Hampshire. So, I returned to my alma mater, thinking I might work on a Ph.D. in operations management, but found out that degree wasn’t offered. Venky (A.R. Venkatachalam), the department chair at the time, asked if I’d be interested in teaching as an adjunct. I figured I’d give it a shot. It was something new and it would allow me to tackle my fear of speaking in front of a group. And, at the time, no group seemed more intimidating to me than a bunch of undergrad students.

I started teaching classes here and there while I was still consulting with corporate clients. Over the years, the balance shifted, and I began teaching more and consulting less. Eventually I became a full-time lecturer and found interacting with students very gratifying and not at all as scary as I thought.

I still love visiting factories. On a recent family trip to Japan, my two sons and I took a tour of the Motomachi Toyota factory. We saw an amazing operation in action: highly talented people and cool robots making cars. The Toyota plant was a more family-friendly field trip than that cigarette factory I visited as a kid way back in the 1970’s."

Miles teaches courses in the decision sciences department and helps facilitate engagement opportunities between business professionals and Paul College students.

-

Written By:

Jody Record ’95 | Communications and Public Affairs | jody.record@unh.edu