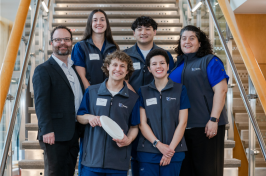

Nick Andrade ’19, captain of the 2019 UNH FSAE Precision Racing team, inspects components at the Kingsbury Hall workshop.

It’s a daunting list of tasks that UNH’s FSAE Precision Racing team has to complete each year to build a car from scratch and get it competition-ready. Since the fall, members of this year’s team of 18 seniors from the College of Engineering and Physical Sciences (CEPS) have put in upward of 60 hours each week developing designs; prototyping, manufacturing and assembling parts; and testing and fine-tuning everything from aerodynamics to electronics to the powertrain. But there’s one item on the annual FSAE punch list that has gotten a little easier in recent years: finding the money to cover the $35,000-$40,000 cost of the car, thanks to the generosity of external sponsors including Pratt & Whitney (P&W), which has supported the project team since 2015.

UNH has competed in the national Formula SAE contest since 2003, regularly lining up against teams with many times its financial resources. FSAE team captain Nick Andrade ’19 says corporate support from P&W and others makes a critical difference to a project that once supplemented its limited budget with t-shirt sales and raffles. “There’s a real trade-off when you only have $5,000 or $6,000 to put toward parts and supplies,” he says. “Corporate support has made it possible for us to purchase sophisticated parts and electronics that not only make our car more competitive, they also give us great hands-on engineering experiences.”

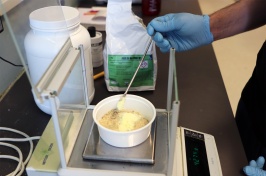

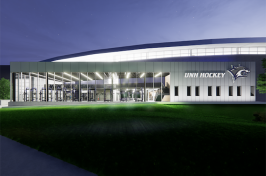

An international aircraft engine manufacture and design company, P&W has longstanding relationships with universities in the STEM (science, technology, engineering and mathematics) disciplines. Mike Newsky ’84, who manages the manufacturing engineering team at the company’s facility in North Berwick, Maine, says P&W’s relationship with CEPS dates back at least 10 years, starting with providing funding to support senior capstone projects. Last June, when CEPS opened its state-of-the-art John Olson Advanced Manufacturing Center, P&W was one of the first companies to step forward with scholarship funds for students gaining real-world manufacturing experience there. More recently, P&W donated a piece of equipment — a deburring cell with a robotic arm that has joined the Olson Center’s impressive lineup of machinery.

Brad Kinsey, the Olson Center’s interim director, says the equipment and the financial support both enhance the learning experience for CEPS students. “The internships, senior projects and hands-on work both at the Olson Center and Kingsbury Hall that have been made possible by P&W’s support give our students the real-world experience that’s central to our mission of aligning academics with industry,” he says.

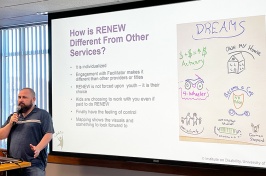

Newsky, who serves on the CEPS mechanical engineering advisory board and the Olson Center board, sees that alignment on his end, and says there’s considerable benefit to Pratt & Whitney, as well. Each year, the company hires CEPS interns and co-op students — who earn both pay and college credit for their work — to tackle a manufacturing project at the plant. A number of these co-op students have gone on to work at the company full-time. “It’s a great partnership,” Newsky says. “It creates a pipeline and gives us some insight into the talent at the university, which is considerable.”