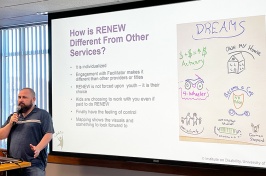

UNH Cooperative Extension field specialist Steve Roberge

Steve Roberge says that equating real maple syrup to store-bought is like comparing apples and oranges. Or more aptly, tree sap and corn syrup. Those who have tasted both will likely agree.

Depending on the weather, the sugarmaking season in New Hampshire runs from February until April. This year, because January was so mild, it started early. Warm days followed by below-freezing temperatures at night are needed to get and keep the sap flowing.

“Some people did catch some sap and made a little bit of syrup,” says Roberge, a field specialist with UNH Cooperative Extension. “It’s not a big deal that some people tap early; we’ve been seeing the season pushed up in recent years. It would only be an issue if it didn’t get cold again.”

Roberge has been conducting free maple-sugaring workshops around the state since February. Two of them focused on first-time tappers. An upcoming March 12 session will discuss small-scale syrup production.

In 2016, New Hampshire produced 169,000 gallons of maple syrup, up from 154,000 gallons in 2015 and 112,000 gallons in 2014. A gallon of Granite State syrup cost $59.10 in 2015; at around $87, Connecticut had the highest price that year.

“Real maple syrup is one of the most natural products you can get,” Roberge says. “And the industry has a whole local economy behind it.” In New Hampshire, that local economy is supported by more than 500 sugarmakers. Conceivably there could be more given New Hampshire’s status as the second most forested state in the country but not all trees are accessible.

“The reality is that not all the sugar maples should be tapped nor can they be. Some sugarbushes may be good trees but you can’t get to them,” Roberge says. “Sugar maples make good wood. There are people who grow maples for timber not tapping. Eighty percent of New Hampshire’s forests are privately owned and all the owners have different philosophies on what they want to do with their land.”

Maple Butter

Boil syrup to about 250˚F. Cool to room temperature.

Beat until creamed. Spread on toast and English muffins.

Store in glass containers.

Maple syrup begins with the starch maple trees store in their trunks and roots. That starch converts to sugar and, in the late months of winter and early spring, rises up in the sap. Sugarmakers place a tap in the tree to collect the sap, which is then boiled down until it becomes syrup.

Says Roberge, “You don’t have to make a big investment to enjoy your own maple syrup. It’s a fairly easy process. If you can boil water, you can make maple syrup.”

Maple Sugaring Tips for Beginners and Backyard Maple Sugar Producers

-

Written By:

Jody Record ’95 | Communications and Public Affairs | jody.record@unh.edu